- Home

- /

- Method

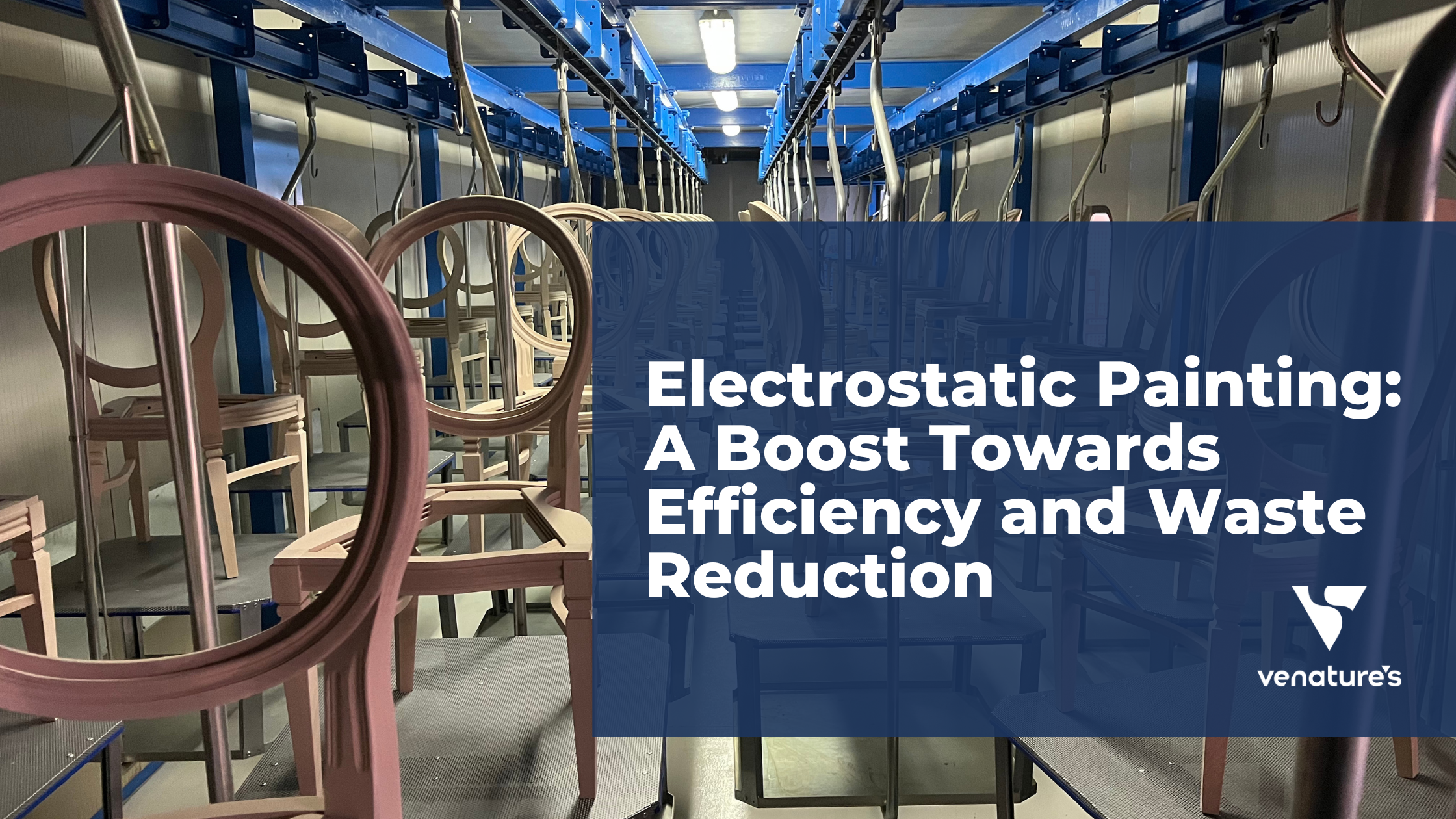

Electrostatic Painting: A Boost Towards Efficiency and Waste Reduction

This article explores the benefits of electrostatic painting, an advanced technique that optimizes waste reduction and enhances production quality. Read how we spared 30% of painting waste thanks to electrostatic painting.

What is the Kanban Method?

The blog post thoroughly explains the Kanban Method, a practice derived from Lean Production, which optimizes workflow and inventory management. Discover the origin of Kanban, how it’s applied in business, and compared to traditional MRP software. Explore the benefits of Kanban, including visual work control, bottleneck prevention, and warehouse cost savings. Find out how much you can save with Kanban and contact us for further information.

Can wood be transformed within 100 metres?

This article discusses the significance of 100 meters in the production process, symbolizing the streamlined efficiency achieved by reducing waste and optimizing workflow, resulting in cost savings, minimized warehouse space, and improved transportation, ultimately adding value to both the company and its customers.

We work to eliminate waste

Eliminating waste is one of our major goals. As already explained in this page, we almost obsessively try to reduce any kind of waste in wood processing and transformation, and we do it considering both raw material and processes.

Our methos in one word: PULL

You find it written on our website, we tell company’s visitors about it, we present it to potential partners. It is Venature’s Pull System®, the method we have chosen to identify our work management system, which over the past few years we have fine-tuned and tailored to our needs. This is why it incorporates our name.

Recent Comments